Gallery

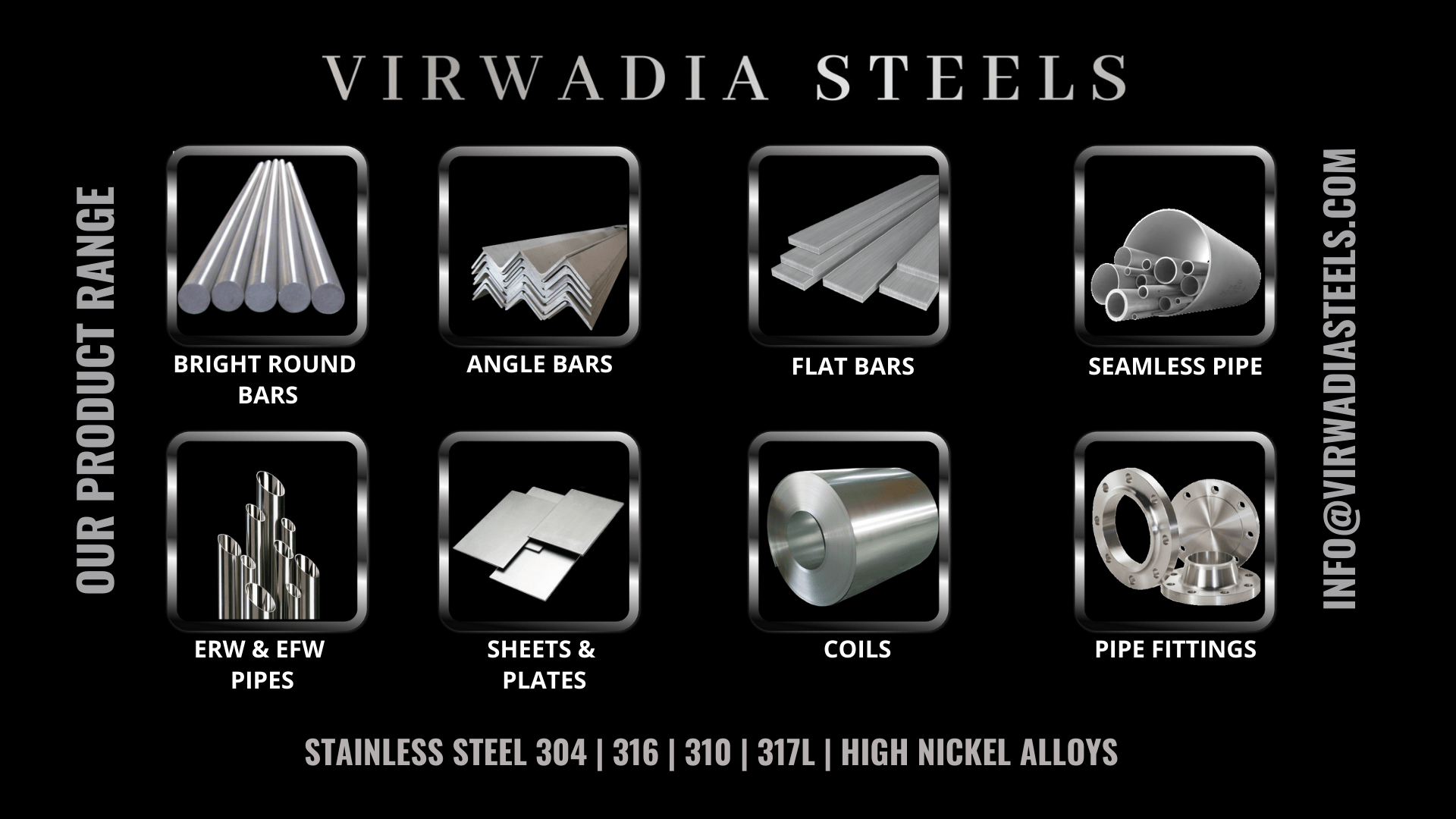

Virwadia Steels is a leading stockiest of Stainless Steel Round Bars, Stainless Steel Sheets, Stainless Steel Plates, Stainless Steel Pipes, Stainless Steel Tubes and Stainless Steel Fittings in Chennai & Mumbai. Virwadia Steels supplies a wide range of Stainless steel both home at and abroad. These Stainless Steel products comes with multiple sizes and various grades which can be customized. Virwadia Steels is a customer focused leading supplier serving many sectors including automotive, building and petrochemical industries throughout the India and the world.

Virwadia Steels is a significant supplier and, in some cases, a manufacturer of a wide array of stainless steel products. They cater to diverse industrial and commercial needs, emphasizing quality and a comprehensive range of grades and forms.

Stainless Steel Grades:

Virwadia Steels offers an extensive selection of stainless steel grades, each possessing distinct properties suitable for various applications. Their typical stock includes:

200 Series:

201, 202: These are chromium-nickel-manganese austenitic stainless steels. They offer good strength and corrosion resistance at a more economical price point than 300 series, often used in less critical applications like cutlery, kitchenware, and architectural trim.

300 Series (Austenitic): These are the most widely used stainless steels, known for excellent corrosion resistance, formability, and weldability.

303: A free-machining grade of 304, achieved by adding sulfur, making it ideal for parts requiring extensive machining.

304 / 304L: The most common and versatile stainless steel. “304” offers good corrosion resistance, strength, and formability. “304L” is the low-carbon version, preferred for welding as it minimizes carbide precipitation and intergranular corrosion.

309S / 310S: High-temperature grades with excellent oxidation resistance, commonly used in furnaces, heat exchangers, and other high-temperature applications. “S” denotes lower carbon content for improved weldability.

316 / 316L: Superior to 304 in corrosion resistance, especially against chlorides and acids, due to the addition of molybdenum. “316L” is the low-carbon version, ideal for welding and marine environments.

316Ti: Contains titanium for stabilization, offering improved resistance to sensitization at elevated temperatures, making it suitable for high-temperature applications requiring welding.

317 / 317L: Enhanced corrosion resistance compared to 316, with higher molybdenum content, often used in aggressive chemical environments.

321 / 321H: Titanium-stabilized grades, offering excellent resistance to intergranular corrosion after exposure to high temperatures (e.g., welding). “321H” has higher carbon for improved high-temperature strength.

347 / 347H: Niobium/columbium-stabilized grades, similar to 321/321H, offering excellent resistance to intergranular corrosion, particularly in high-temperature applications.

904L: A super austenitic stainless steel with high nickel, chromium, and molybdenum content, providing excellent corrosion resistance in severe environments, including sulfuric acid.

400 Series (Ferritic & Martensitic):

409 / 409M: Ferritic stainless steels, offering good corrosion resistance and formability, often used in automotive exhaust systems.

410 / 410S: Martensitic stainless steels, heat-treatable for high strength and hardness. 410S has lower carbon for better weldability. Used in industrial components, fasteners.

416: A free-machining martensitic grade, often used for shafts, valve parts.

420: A martensitic grade with higher carbon content, offering good hardness and wear resistance, suitable for surgical instruments, cutlery.

430: A common ferritic stainless steel with good corrosion resistance and formability, often used in appliances and decorative trim.

440C: A high-carbon martensitic stainless steel with excellent hardness and wear resistance, used in bearings, knife blades.

Duplex & Super Duplex Steels:

Duplex 2205 (UNS S31803 / S32205): Combines properties of austenitic and ferritic stainless steels, offering high strength and excellent resistance to pitting and stress corrosion cracking.

Super Duplex 2507 (UNS S32750 / S32760), Zeron 100: Even higher strength and corrosion resistance than standard duplex, ideal for highly corrosive environments in oil & gas, chemical processing.

Precipitation Hardening Steels:

17-4PH: A martensitic precipitation-hardening stainless steel, known for high strength and hardness, often used in aerospace and medical applications.

Stainless Steel Forms:

Virwadia Steels supplies stainless steel in a comprehensive range of forms, meeting diverse industry requirements:

Sheets, Plates & Coils: Flat products in various thicknesses (thin sheets, thicker plates) and continuous rolls (coils) for fabrication, construction, and manufacturing. They also offer perforated sheets, checkered plates, slit bands, and shim foils.

Bars:

Round Bars: Solid cylindrical bars, including bright round bars, precision round bars, peeled round bars, hot-rolled, and cold-drawn.

Flat Bars: Solid rectangular sections, including true flat bar and sheared and edged.

Square Bars: Solid square sections.

Hex Bars: Solid hexagonal sections.

Rectangular Bars: Solid rectangular sections.

Forged Bars: Bars produced through a forging process for enhanced mechanical properties.

Rods: Typically smaller diameter round bars.

Pipes & Tubes: Hollow sections available in:

Seamless Pipes/Tubes: Produced without a weld seam, offering high strength and integrity.

Welded Pipes/Tubes: Formed from flat strip and welded along the seam.

Capillary Tubes, Small Diameter Tubes, Precision Tubes, Surgical Tubing, ERW Pipes.

Mirror Polished Pipes: For aesthetic and sanitary applications.

Fittings: Components used to connect pipes and tubes, including flanges and pipe fittings.

Structural Sections:

Angles: L-shaped profiles.

Channels: U-shaped profiles.

H-Beams & I-Beams: Heavy structural profiles.

Virwadia Steels emphasizes their capability to provide “cut to size” materials and handle orders of varying quantities, from small to large. They are positioned as a “one-stop destination for all your metal requirements” in Chennai & Mumbai, serving customers across India and internationally. They source materials to high industry standards and provide Mill Test Certificates as per EN 10204 3.1.

Stainless Steel 304 Round Bar in India

Stainless Steel 304 Round Bar Near me

Stainless Steel Jindal Sheets 304 & 304L

Stainless Steel 304L in Chennai

Round Bar virwadia steels Stainless Steel 316

Round Bar Stainless Steel 317L Rod, Pipe, Sheet

316H Round Bar Stainless steel in Chennai

Steel 316L Round Bar Chennai Virwadia

SS Round Bar Stainless Steel 316L,321,310,347

Round Bar Stainless Steel 310S/H India

Seamless Pipe Stainless Steel in Mumbai

Steel 321 Round Bar Stainless dealers

Stainless steel Virwadia steels suppliers 321H Pipe

Inconel 625 Round Bar in Chennai

Stainless Steel 347H Rod at virwadia steels

Stainless Steel 316Ti Round in India

Stainless Steel 316 suppliers in India

Stainless Steel 304 Suppliers & Manufacturers

310 Round Bar Stainless Steel Dealers

SS 321H Round Bar manufacturers

Stainless Steel 347 Round Bar Dealers

Stainless Steel Round Bar 304,316,310,321 & More

Aluminium 6061, 6083, 7075 & Many More

Inconel, Monel, Hastelloy Suppliers in india

Stainless Steel Dealers S31803 chennai

Duplex & Super Duplex Round Bar

Hastelloy C726 Round bar & Pipes India

Nitronic 60 (Alloy 218, UNS S21800) in India

STAINLESS STEEL

ALUMINIUM

COPPER & BRASS

NICKEL ALLOYS

TITANIUM

ALLOY STEEL

MILD STEEL

tool steel

Lead

Special alloys

MANY MORE!